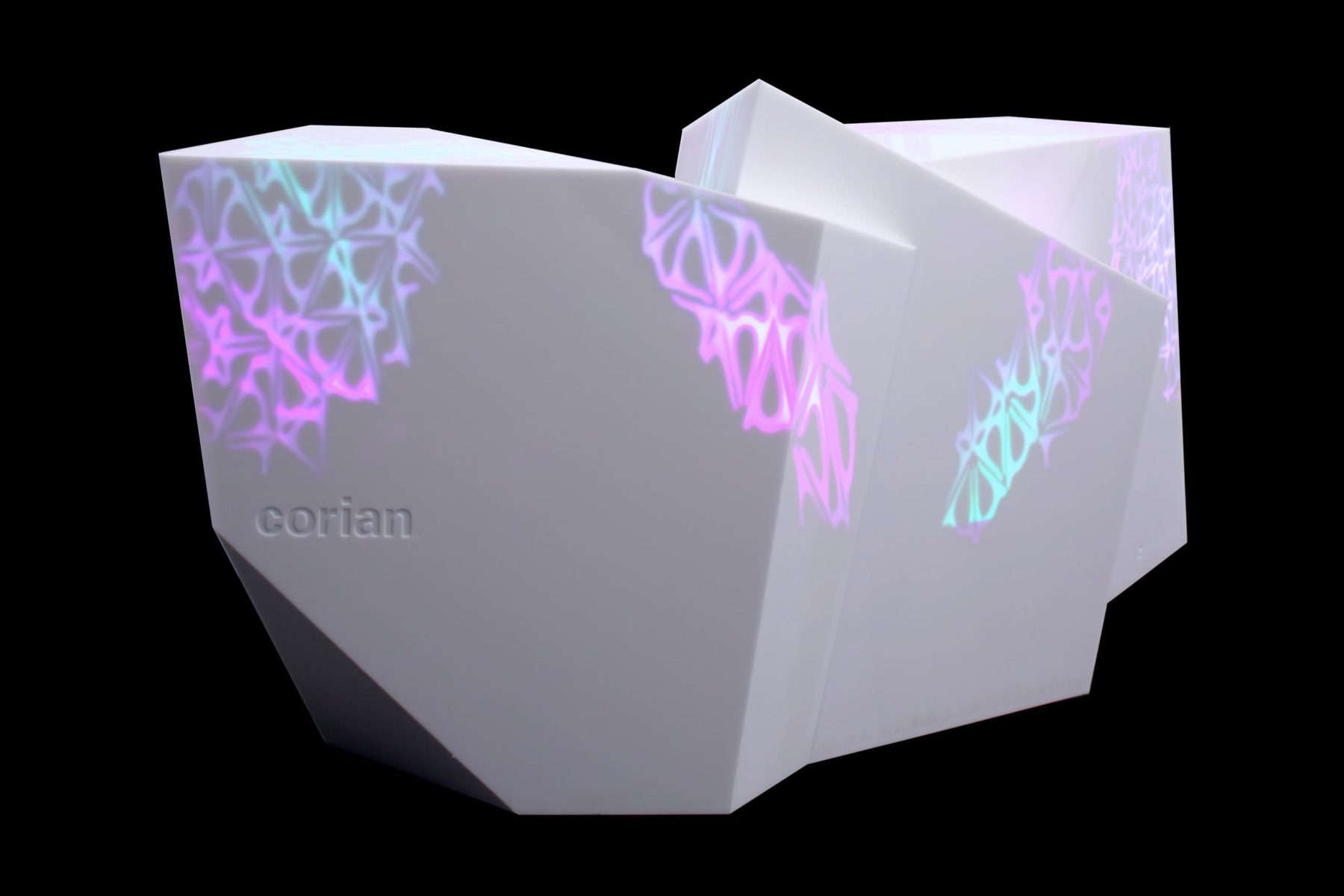

With Corian® DuPont™ has developed a solid mineral material that is popular with architects and designers and suitable for bathrooms as well as for tactile exhibits in outdoor spaces with heavy public traffic.

Corian® scores with the following properties:

- high-quality, stone-like feel

- homogeneous, non-porous surface

- waterproof and antibacterial

- joint-free bonding

- wide range of colours

- durable

- easy to rework and repair

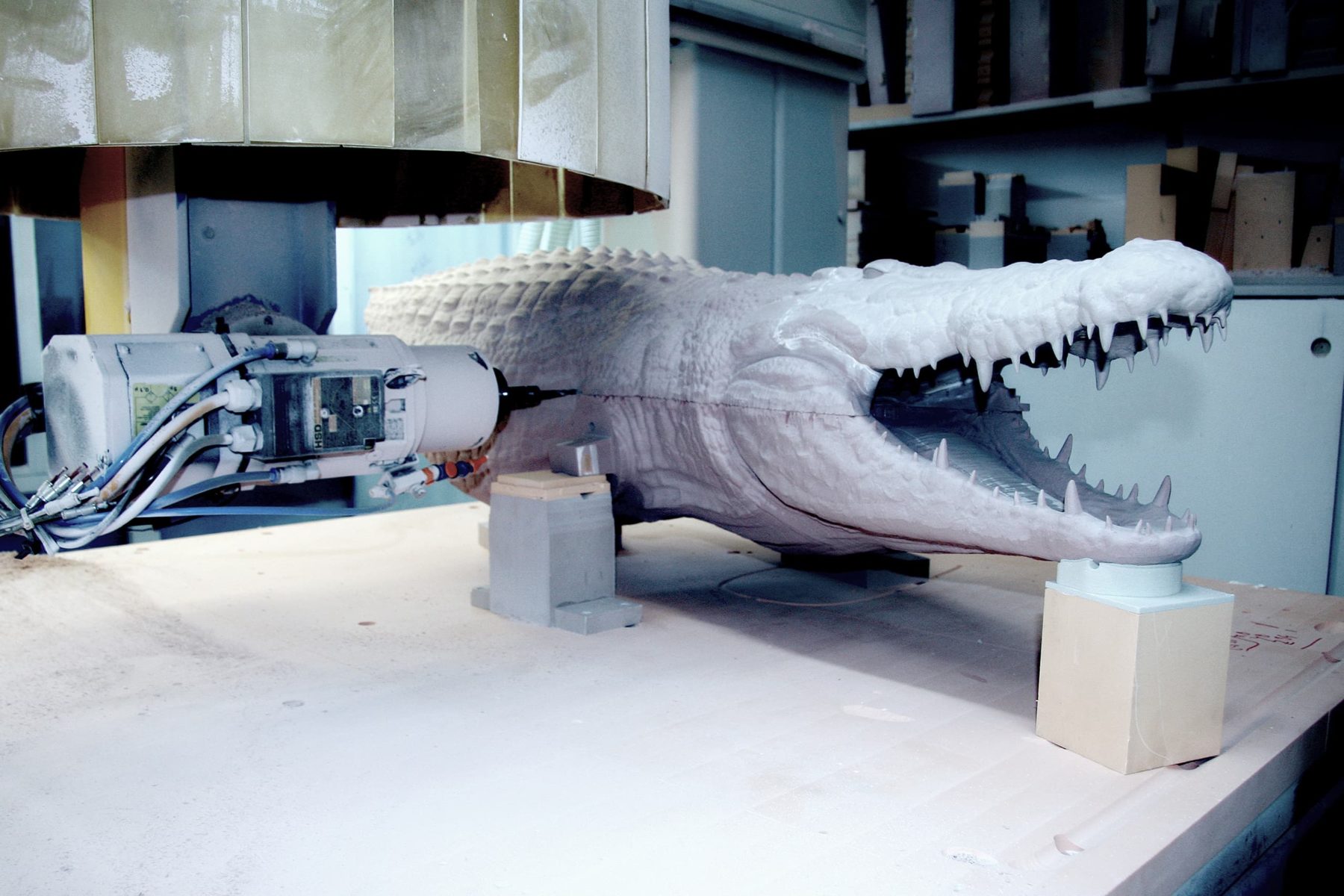

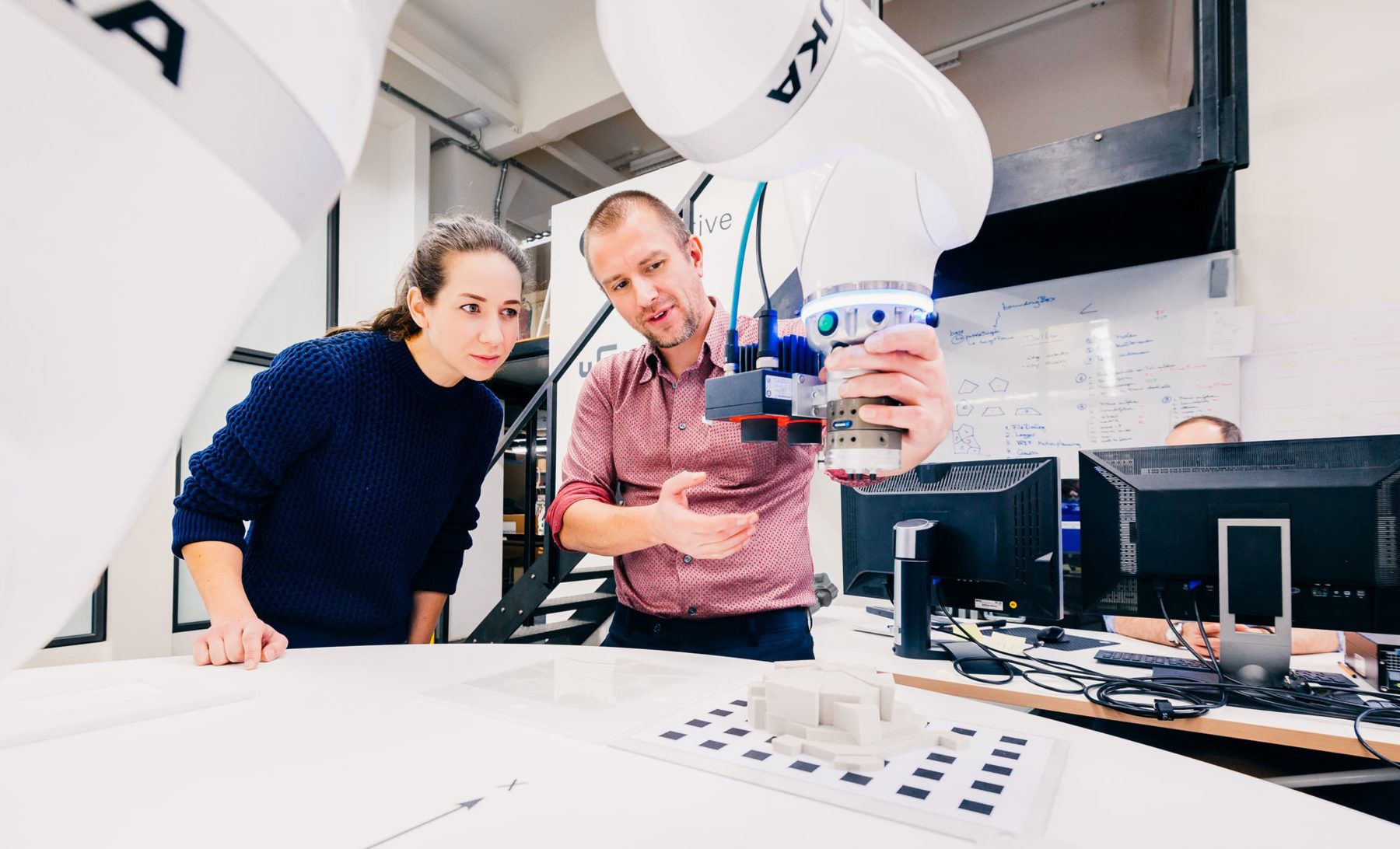

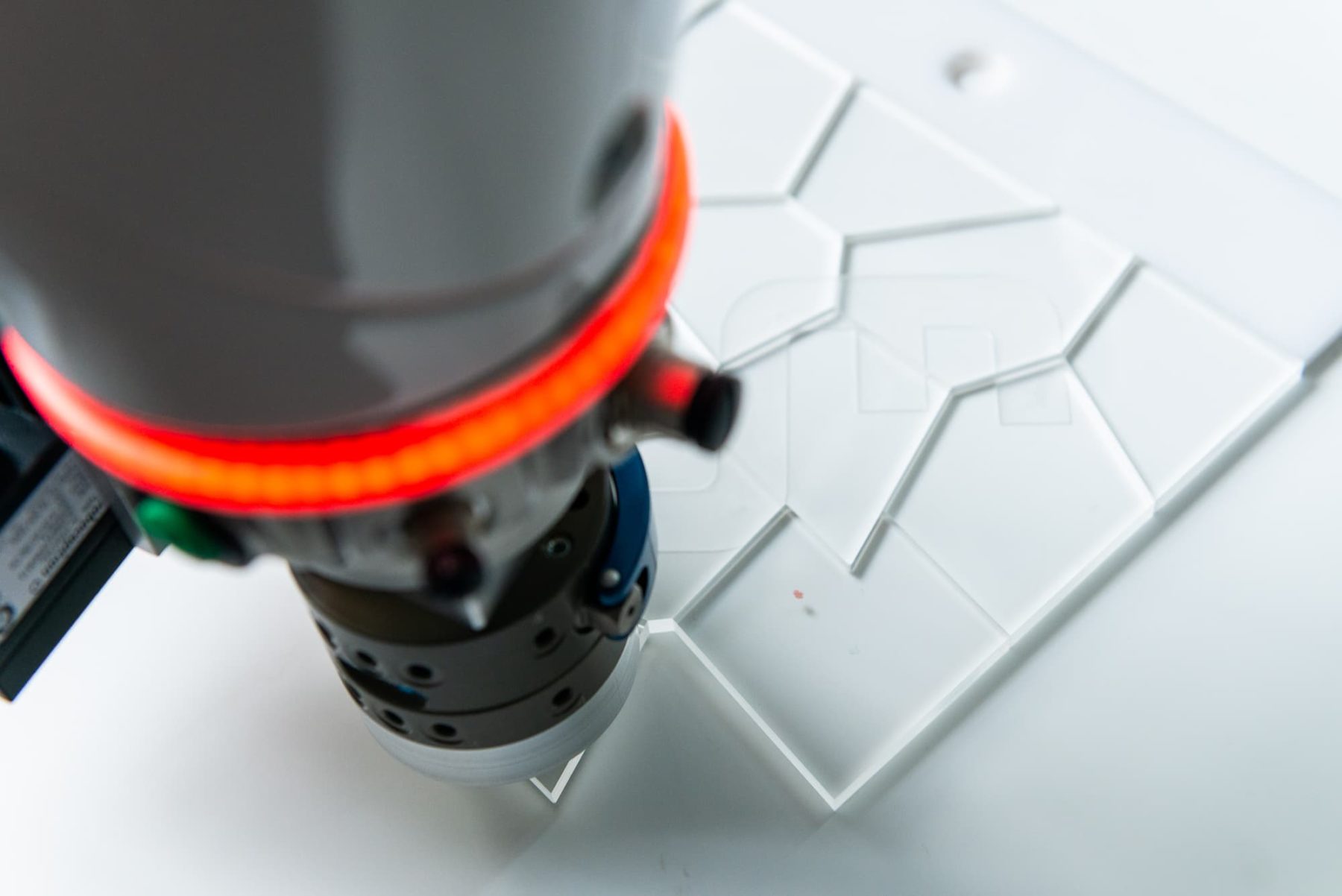

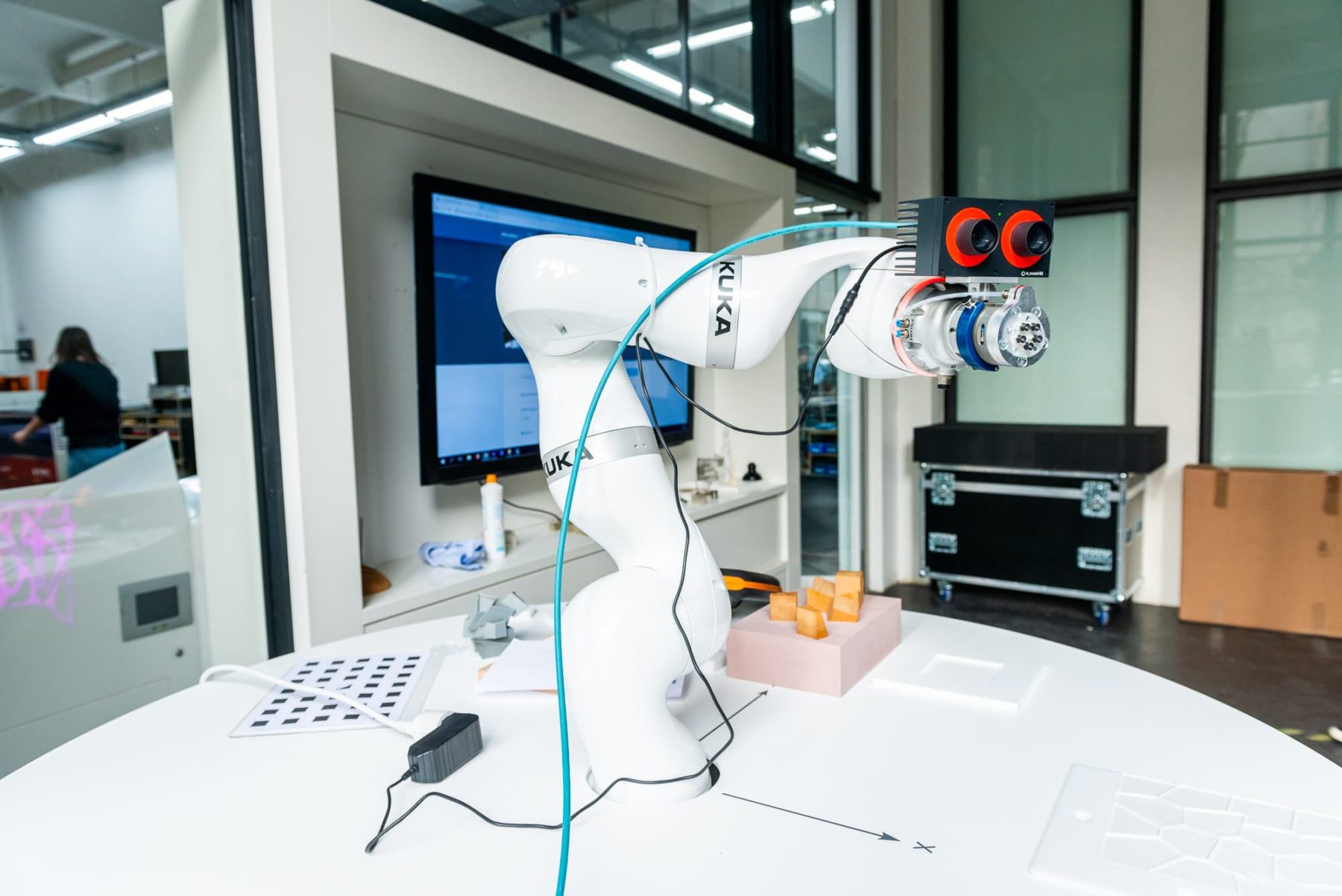

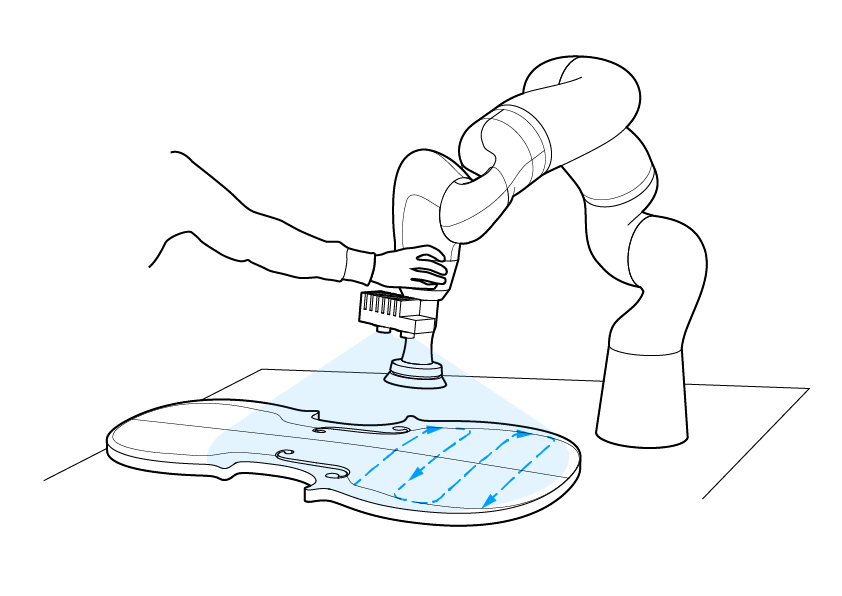

- versatile processing possibilities from thermoforming to CNC-milling

Another advantage for you: as a certified Quality Network partner of the DuPont™ company, we give you a ten-year guarantee on the material!

Corian®